plastic recycling machine

Pet bottle plastic granules recycling machine

We are able to supply a wide range of recycling machine, including plastic recycling machine, PET bottle recycling machine, LDPE film recycling machine, wasted water treament machine, garbage and junk recycling machine, wasted tyre recycling machine, wasted glass recycling machine, etc.

Features of pet bottle plastic granules recycling machine

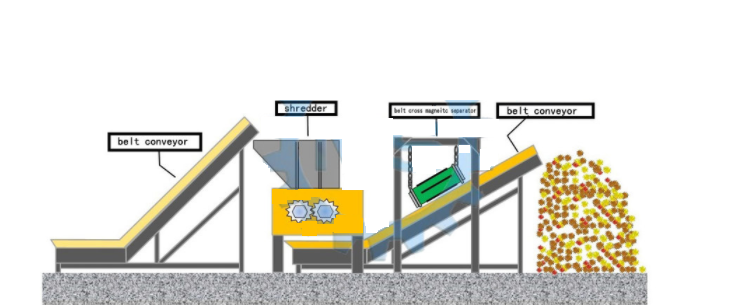

1, feeding conveyor

2, shredder

our shredders are built to laste , with a siemens motor and schneider components utilized our range of waste shredders can cope with whatever material you wish to shred . add other parts to make it a recycling line and you can remove ferrous and non ferrous metals, the bales material is dilliner brand ( from Germany) they shred by size and even have various loading /unloading options to suit your requiments. using German made blades, that are easily replaceable and in stock , your machine will be work horse for your business.

check the catalog

for plastics/rubber scrap or other solid waste recycling, Enerpat dual shaft shredders are being used for the recycling of plastic film, woven sacks, plastic drums, used computer and office machines, as well as wooden pallets.

we can also supply custom made shredders for other applications. Example of our special shredders include computer hard drive shredders, e-scrap shredders, cardboard shredders, and plastic foam shredders.

3, crusher

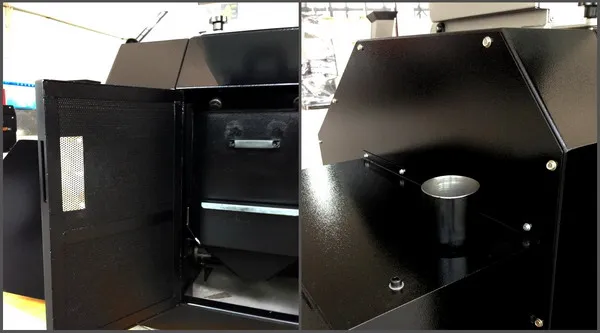

Pictures of plastic crusher with extra suction blower and cyclone silo

check the catalog

Specifications

| Model | S5.5 | S7.5 | S11 | S15 | S22 | S30 |

| Motor power (kw) | 5.5 | 7.5 | 11 | 15 | 22 | 30 |

| Motor optional (kw) | 7.5 | 11 | 7.5/15 | 11/18.5 | 18.5/30 | 22/37 |

| Rotating speed (rpm) | 600 | 500 | 500 | 480 | 480 | 480 |

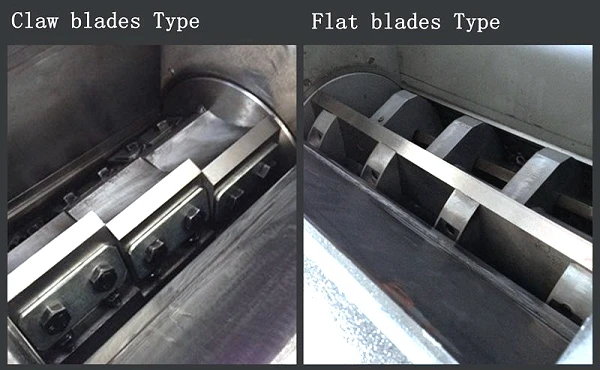

| Knives material | SKD-II | SKD-II | SKD-II | SKD-II | SKD-II | SKD-II |

| Claw moving knives (pcs) | 9 | 12 | 15 | 18 | 21 | 24 |

| Optional Flat knives (pcs) | 3 | 6 | 6 | |||

| Fixed knives (pcs) | 2 | 2 | 2 | 2 | 4 | 4 |

| Rotating Dia. (mm) | 230 | 250 | 260 | 300 | 360 | 400 |

| Crushing chamber (mm*mm) | 230*300 | 250*400 | 260*500 | 300*600 | 360*700 | 400*800 |

| Screen Hole Dia.-standard (mm) | 8 | 8 | 8 | 8 | 8 | 8 |

| Screen Hole Dia.-optional (mm) | 4,6,10,12,14,18,25 | |||||

| Hardened Screen | o | o | o | o | o | a |

| Manual Bin | s | s | s | s | s | b |

| Blower | o | o | o | o | o | a |

| Dust Separator | o | o | o | o | o | a |

| Noise Enclosed Cover | o | o | o | o | o | a |

| Crushing Capacity (kg/hr) | ≤200 | ≤300 | ≤450 | ≤550 | ≤650 | ≤900 |

| Sound pressure level (dB) | 75-90 | 75-95 | ||||

| Dimensions (L*W*H) (mm) | 930×680×1120 | 1150×820×1280 | 1200×880×1400 | 1230×1020×1520 | 1460×1200×1700 | 1500×1350×2100 |

| Weight (kg) | 400 | 550 | 850 | 1000 | 1200 | 2000 |

Notes: 1) “s”standard, “o”optional

2)Throughput capacity depends on type of plastic material,waste,etc. 3)Sound pressure level depends on type of material and motor. 4)To avoid sticking knives,material must be in normal temperature. Half-inclosed Type: Manual Bin Full-inclosed Type: Be installed with blower & Cyclone silo & Noise Enclosed Cover. "Q" TYPE | ||||||

Below is machine pictures:

Below is the Type : Be installed with blower & Cyclone silo & Noise Enclosed Cover.

contact way :

Comments

Post a Comment